COMMITMENTS AND ACHIEVEMENTS

Patent

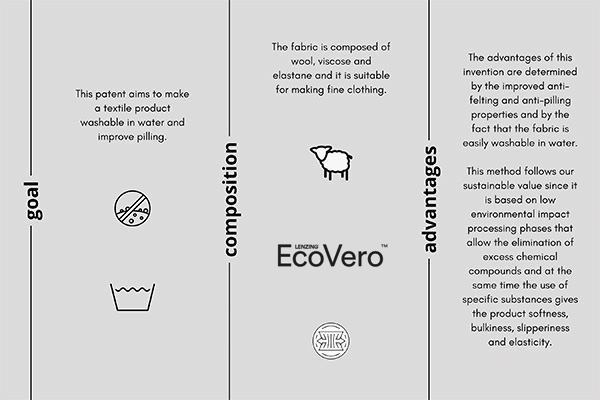

We have enriched our “way of making fabrics” with a very important and innovative process patent called “Method for finishing a textile product and related fabric”.

We recognize the importance of eliminating dangerous substances from our production cycle, which is why in March 2016 we signed the Detox commitment, promoted by Greenpeace. This important improvement process has allowed us to start our constant commitment to respecting the environment and the health of workers and consumers through quality products and processes.

We share this duty with a group of companies in the Prato textile district, with the coordination of Confindustria Toscana Nord which deals with the management of environmental sustainability in companies in the fashion system supply chain. It was born as a reaction to a challenge launched by Greenpeace: to eliminate substances that are toxic to humans and pollutants for the environment from clothing.

Thanks to analyses, studies and research, it is possible to demonstrate that an eco-sustainable fashion is possible, as evidenced by the survey on textile dyes, made public on the occasion of the official presentation of the CID, in October 2016.

It is much more productive to work together with companies with the same objectives, relying on the coordination of activities by a structure capable of providing constant technical-scientific support.

The results have been visible in the elimination of 8 groups of dangerous chemical substances from our industrial processes, to reach the ambitious goal of eliminating 11 groups of harmful substances in 2020.

So the next objectives of the CID are to investigate the aspects of manufacturing production still to be examined to understand where and how to intervene to safeguard our health and the future of the environment.

Texmoda Tessuti has conducted a program of chemical tests to control its production process and identify the materials, products and processes in which the risk of the presence of APEO and AP is greatest.

The aggregated results of the study conducted by the group of Detox companies in the Prato district are published on the Confidustria Toscana Nord website:

www.confindustriatoscananord.it/sostenibilita/detox

The analyzes were carried out on representative samples of our production as they cover a significant percentage of our turnover.

NEW TESTS 2023

For more information on the Detox project of Confindustria Toscana Nord

www.confindustriatoscananord.it

Learn more about the Detox campaign

www.greenpeace.org/italy/it/campagne/inquinamento/acqua/Campagna-Detox/

www.greenpeace.org/italy/cosa-facciamo/